Rows of holes for wire comb binding / wire-o®-patterns

Drilling is a much more efficient process compared to punching if pitches 2:1 and 3: 1 are needed. Stacks up to 50 mm can be drilled in one operation. Many materials – cardboard, paper in different grammages, films and plastic covers – can be drilled all together after collating the brochure.

High performance paper drilling - paper drilling system PB.15

Automated paper drilling process with minimum changeover time: Dürselen PB.15 paper drilling system reaches an output up to 1,500 piles per hour for loose leafs as well as for perfect bound and stitched brochure and folded sections.

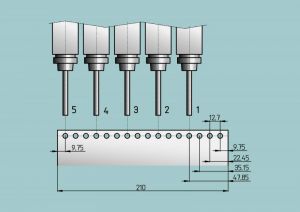

Drilling narrow hole spacings - Paper drill PB.16 with motorised sliding table

Paper drilling machine PB.16 with electrical sliding table - for narrow hole spacing like mechanical binding / wire-comb binding