- » Product description

- » Technical data

- » Performance data

- » Video

Product description

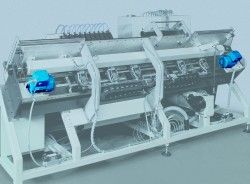

The automated paper drilling system Dürselen PB.15 joggs and drills

- Piles of loose leafs

- Piles of folded sections

- Piles of perfect bound books and

- Piles of stitched brochures

up to 50 mm / 2" in height at an output of approx. 1,000 piles per hour on standard hole patterns, up to 700 piles per hour on hole patterns for twin wire / mechanical binding.

Additionally to its high performance flexibility is the main feature of this paper drilling system. This includes automatic push button paper size change and spine margin adjustment via touchscreen. The only manual set-up operation is positioning of the drill heads - so job changeover is done very quickly.

Dürselen PB.15 includes all features of a modern paper drilling system. The transport channel consists of chrome-plated, polished rollers and air-cushioned sheet metal plates. The drill belt as drill support has a motorized programmable transport function. To avoid sticking of the bottom sheet to the drill belt each pile is carefully lifted before being moved out of the drilling station.

Paper drill Dürselen PB.15 can be used flexibly in-line and as a stand-alone system - high performance paper drilling in perfection.

Technical data

- 4 Drill heads, up to 11 standard heads and special multispindle drill heads possible

- Continuously variable stroke and spindle speed

- Drill belt as drilling support with motorized, programmable transport

- Automated spine margin setting

- Paper drill bit cooling and lubrication system

- Spine margin behind drill bits 5 - 25 mm / 3/16" - 1"

- Closest hole spacing 1 mm / 3/64"

- Paper drill bit diameter 3 - 14 mm / 1/8" - 5/8"

- Minimum paper size 120 mm / 4 3/4" long x 80 mm / 3 1/4" wide

- Maximum paper size 340 mm / 13 1/2" long x 320 mm / 12" wide

- Pile height up to 50 mm / 2"

- Dimensions incl. conveyors 2,600 mm / 102" wide x 2,400 mm / 95" deep x 1,300 mm / 51" high

- Power requirements 400 volts, 3 phases, 50 - 60 cycles, 25 A, 7.5 kW (10 HP)

- Compressed air consumption 250 litres / minute at 6 bar pressure

Options:

- Internal impulse lubrication for the paper drill bits

- Drill bit breaking sensors for in-line-operation

Performance data

- Up to approx. 1,000 piles per hour on standard hole patterns

- Up to 700 piles per hour on twin wire / mechanical binding hole patterns - a highly efficient alternative to automated punching

- Automatic push button paper size change

- Change of hole pattern in 2 minutes

- Automatic push button spine margin adjustment

- Interactive short stroke function for increased productivity with low pile heights

- Touch screen with easy menue navigation

- Careful material transport by flat feeding of piles and smooth, air-cushioned transport channel

- Intelligent transport and positioning system

- Job memory and recall for repeat work inclues all drilling parameters

- Optional external interface for job data transfer by network or barcode driven

- Changeover from in-line to off-line configuration in less than 10 minutes

Video

High performance paper drilling - paper drilling system PB.15

Automated paper drilling process with minimum changeover time: Dürselen PB.15 paper drilling system reaches an output up to approx. 1,000 piles per hour for loose leafs as well as for perfect bound and stitched brochure and folded sections.